This PVC sheet is a moderately expanded high density, polyvinyl chloride (PVC) sheet. As a lightweight plastic material, it can be used in the field of building and construction, concrete forming, furniture industry and advertising billboard as well as signage and engraving, etc. The different types of panels have different properties and features according to their applications using different extraction technologies such as Celuka foam semi-celuka foam and Co-extrusion etc. The panels can be easily cut, sawed, drilled, and fabricated. The sheet is an excellent material for model exhibits and displays. For interior signage Can be painted and silk-screened. Its characteristics include: foamed PVC sheet material that is approx half the weight of solid PVC; durable and hard-wearing under many adverse conditions and resists most chemicals and water, with its porous interior and hard smooth surface;

Extrusion technologies | Thickness range (mm) | Density range (g/cm3) | Properties | Application environment

|

| Free foam | 5-35mm | 0.3-0.8 | Fine celled foam structure, good surface strength. Glossy and matt surfaces,UV resistance | Excellent substrate for printing, painting, engraving, and laminating. interior signage, displays, and billboard |

| Celuka | 5-35mm | 0.3-1.2 | The higher density with rigid crust surfaces, high impact strength, smooth and solid, chemical resistance Can be UV resistant | Exterior formwork, furniture manufacture, external work, interior application replacing wood and other panels |

Plastwood | 4-25mm | 0.45-0.55 | PVC Trimboard, solid and rigid structure, easy to cut and shape, nailing, and painting. low flammability rate. | Substitute for real wood used in building and construction, also be used for industrial manufacturing. |

| Co-extrusion | 5-35mm | 0.5-0.55 | 3 layers of the compact sheet, Rigid skin surfaces, glossy and shiny white, resistant scratching. Foamed core | Exhibition stand, cabinet, concrete forming, out-door furniture making, fencing, etc. |

Technical data sheet sample tested by Interteck

| Properties | Standard | Samples | Test | Value |

| Physical (All thicknesses of samples are produced as 500kg/m3 The test value will be going higher if the density is higher) |

| Density | In house | 15mm |

| 536kg/m3 |

| Hardness | ISO 868:2003 | 15mm |

| 61.3 |

| Water absorption | ISO 62:2008 | 5mm |

| >240 .VICAT(oC) |

| Mechanical |

| Fastener Withdrawal | ASTMD6117-1 | 15mm | Screw holding | 727N |

| Tensile properties | ISO 527-4:1997 | 5mm | Tensile strength | 4.1MPa |

| Elongation | 3.4% |

| Tensile modulus | 491%

|

| Chemical properties |

| Effect of stains | ISO 26987:2008 | 15mm | Flowing water | Acetic acid: Slight |

| Sodium hydroxide: not affected |

| Unleaded gasoline: Slight |

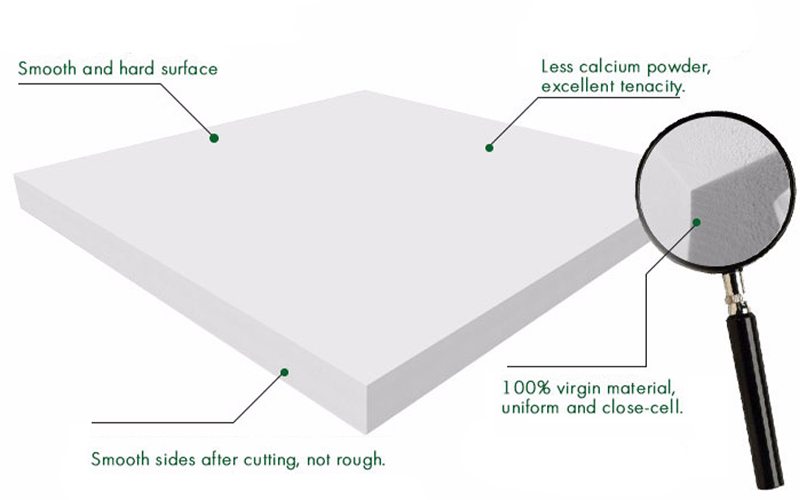

Free form PVC sheet

Our free-foam PVC sheets are expanded PVC panels which exhibit a regular, fine-celled foam structure and uniform surface. The closed, matt, fine-textured, and high-quality surface presents an excellent substrate for multi-purpose advertising panels when it comes to printing, painting, and laminating. Excellent properties offering the best conditions for great design potential which is, therefore, an interesting solution above all for advertising and building applications. Whether for signs, banners, or displays. In the color white the sheets are even weatherproofed and weather-resistant, making them the ideal material for outdoor applications as well. UV stabilized surface is available for exterior advertising use such as digital printing, PoP , Lettering; etc.

Advantage

• lightweight, good tenacity, high rigidity n

• fireproof and flame retardant

• good insulation

• no sopping, no deformation

• easily to processed

• good plasticity, flexible, being an excellent thermoform

• sub-light surface and elegant vision

• anti-chemical corrosion

• suitable for silk screen printing

• with imported dyes, unfading and anti-aging

Celuka foam sheet

Our celuka foam sheet is a lightweight closed-cell, rigid crust skin PVC sheet. The surface can be matte and glossy with which is clean. The colors can be white and colored. The matte surface is the perfect substrate for screen printing, painting, laminating, vinyl lettering and forming projects. It can be sawed, drilled, bent and fabricated using ordinary tools and fasteners. It is easy to be thermal shaped, bend, and form. Ideal for a variety of uses such as advertising materials, Furniture manufacturing, construction finishing materials and industrial applications etc. Our high-gloss surface with UV resistant film lamination is extremely versatile for out-door advertising and vinyl lettering use.

Properties & feature

• Excellent for signs, displays & model exhibits

• Attractive surface is easy to clean

• For interior signage only

• Porous interior & hard smooth surface

• Flammability rating UL 94 V-O

• Approximately 1/2 the weight of solid PVC

• Durable & hard-wearing under many adverse conditions

• Resists most chemicals like alkalis and weak acids

• Good sound dampening properties

Application:

• Advertising: Exhibition & display, digital printing, silk screen printing, engraving, signboard, etc.

• Furniture: Office furniture, cabinet, bath cabinet, etc.

• Construction: Finishing Material: substrate of decorative sheets, storage racks, room segments, etc.

• Industry: Thermoforming products, freezing warehouse project, environmental protection.

• Transportation: boats, planes, buses, cars, coach, roof, core board, interior decorative panels

Specification

| Thickness | 3-30mm |

| Density | 0.45-0.7 g/cm3 |

| Hardness range: | 30-60 D |

| Standard color | White, other color board available |

| Surfaces | Smooth & rigid, high glossy UV resistant film laminated. |