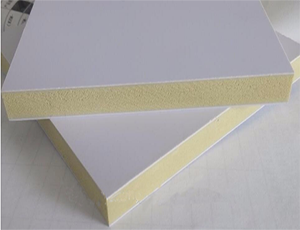

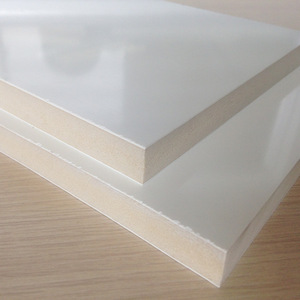

PVC Co-extruded Foam Sheet (Polyvinyl chloride co-extrusion foam board) is made with the special co-extrusion production process, technique, and equipment, which forms a sandwich board structure. Both surfaces of the sheet are not foam but rigid, while only the core is foam. It is like a sandwich board with thin surfaces in a one-time process. The advantage of this product is its hard surface like Rigid PVC sheet but in lighter weight and lower cost. Comparing with PVC celuka foam board, PVC co-extruded foam has a smoother and shiny surface. The surface hardness is much better than celuka, which will benefit from using in some application

PVC Co-extruded Foam Sheet (Polyvinyl chloride co-extrusion foam board) is made with the special co-extrusion production process, technique, and equipment, which forms a sandwich board structure. Both surfaces of the sheet are not foam but rigid, while only the core is foam. It is like a sandwich board with thin surfaces in a one-time process. The advantage of this product is its hard surface like Rigid PVC sheet but in lighter weight and lower cost. Comparing with PVC celuka foam board, PVC co-extruded foam has a smoother and shiny surface. The surface hardness is much better than celuka, which will benefit from using in some application

Features:

Flexible;

Water-proof

Lead-free, Non-toxic;

Excellent Formability

Perfect Machinability;

Outstanding printability;

Lightweight, easily reassembled

Excellent Chemical and Corrosion Resistance;

Application:

It is a lightweight, expanded rigid PVC foam board that is used for a variety of applications including signs and display, exhibit booths, photo mounting, interior design, thermoforming, prototypes, model making. Comparing with PVC celuka foam board, PVC co-extruded foam has a smoother and shiny surface. The surface hardness is much better than celuka, which will benefit from using in some applications, such as tabletop, interior decoration for boats, ship, vehicle, train.

Product properties

• Color of outer skins: white, Other colors available

• Colors of core: yellow, green, or black, etc.

• Antistatic

• UV and weather-resistant

• High dimensional stability

• Excellent processing characteristics

• High-quality appearance

Areas of use

• Structural engineering

• Shipbuilding

• Signage, display and exhibition stand design

• Swimming pool construction

• Stadium construction

• Livestock farming and agriculture