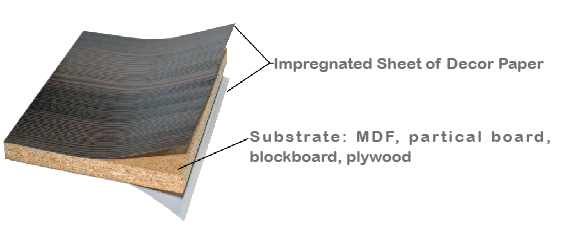

Thermally-Fused-Laminates (TFL) are made by melamine-resin décor papers applied directly by heat and pressure to a substrate penal. Under high heat and low pressure, the decorative layer binds to the board without the need for adhesive. The chemical reaction during the thermal process makes the finish impossible to peel away from the substrate. Heat and pressure activate the resin in the saturated TFL panel sheet, creating a cross-linked bond with the substrate. This effectively seals the substrate. Particleboard and MDF are ideal substrates for TFL because they are consistent, uniform in strength and free of defects.

| |  |

| Constructure of TFL penal |

| Download pdf |

TFL Panels are used in the following: Thermally fused laminate (TFL) decorative panels can be manufactured with enhanced visual and performance characteristics. Surface textures are created with steel press plates that emboss the decorative overlay to heighten the realism of wood grain, stone or abstract designs. Steel press plates can also be used to create or control the gloss level of the surface. TFL decorative panels have excellent scratch and wear resistance. They are widely used in laminate flooring, office furniture, closet system components, store fixtures and cabinets. It is also an appropriate spec in health care, hospitality, commercial and retail settings. TFL decorative panels typically require a decorative edge treatment and can be specified with or without edge, and with single or opposite-side face treatments. Due to the performance, design flexibility and cost advantages, TFL offers an excellent option for designers and specifiers.

● Laminate Flooring

● Office Furniture

● Closet System Components

● Store Fixtures

● Cabinets

It is also an appropriate spec in healthcare, hospitality, commercial and retail settings. TFL panels typically require a decorative edge treatment and can be specified with or without edge, and with single or opposite-side face treatments.

Thermally Fused Laminate (TFL) also offers excellent hardness and scratch resistance that can stand up to the high demands of many environments.

Surface treatment:

Synchronized textures and finishes are defined as aligning patterns and texture in an effort to replicate a product as it exists in nature. Thermally fused laminate (TFL) producers work in harmony with décor print suppliers and press-plate designers to ensure the pattern (often woodgrain) and texture are perfectly aligned in each and every press cycle. The perfectly matched and indistinguishable from real wood veneer. Synchronized textures are available as a two-sided product, providing a great deal of flexibility to designers and fabricators.

A mirror sheen finish, which gives a smooth, brilliant appearance, Recommended for horizontal applications such as countertops and light-to-medium commercial applications. Excellent for vertical application.