Introduction

Recon Veneer is a kind of engineered veneer or reconstituted veneers. They are similar in the fact that they are both wood materials. It is man-made or manufactured veneers made with the process of dyeing, laminating, and re-slicing. You can obtain the desired color and pattern. Recon wood veneers are made of actual wood from fast-growing trees in managed forests. It is a renewable product and an environmentally friendly alternative to some of the rarer and extremely expensive veneers.

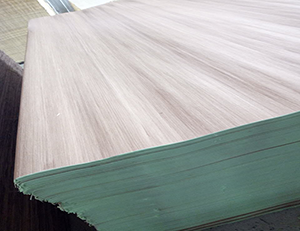

Fantastic wood grain design of Recon Veneer

Recon Veneers will give you consistency in grain pattern and color, like laminate but because they are actual wood fibers, they are flexible and natural in texture and appearance. it is a substitute good of hardwood veneers just like okoume, pencil cedar, sapeli as well as Teak and Walnut and so on.

Veneer – authentic structures and a large selection of colors are the prominent features of our veneer collection. Combinations of different décors out of the collection create a pleasingly warm and harmonious impression. The surfaces of our Veneer laminates consist of reconstituted veneers. For the production of reconstituted veneers, peeled veneers from poplar or ayous wood are partly dyed, rejoined together in layers and pressed to a block from which the reconstituted veneers are sliced. By putting together different dyed veneers and using special methods of pressing the most popular, even exotic species of timber can be reproduced. Valuable resources are saved this way, without having to give up special and extravagant décors. We press these reconstituted veneers in the well-known production process to laminates. The surface is finally melamine coated and covered with a protective film. Due to the manufacturing process, the appearances of the veneer deviate only slightly from laminate to laminate or from sample to sample and illustrations. However, it is a natural product with all the typical characteristics of wood.

1. ROTARY CUT VENEER

The timber logs are rotary cut to produce the veneer. We do this by rotating the log around its axis. A knife is positioned against the log to peel off a thin layer of wood. During this process, all the veneer nature defects have to be repaired. The veneers in the same layer are well jointed.

2. DYEING

Dyeing is a very important part of the process when producing a reconstituted veneer. The veneer strips are submerged in a bath of water at a specific temperature and with the required dye concentrate. The dyeing process uses 100% water-based dyes. No heavy metals or other toxic substances are used. The reconstituted veneer strips are dyed multiple times to ensure colorfastness. Real wood imitation can be designed for different images.

3. CREATING THE PATTERN

The dyed veneer strips are mixed to produce the desired reconstituted wood species or design.

4. GLUING

The pile of the veneer is glued after stacking as a block. Glue is applied to each strip.

5. PRESSING

After gluing, the veneer block is formed in a press machine.

6. DRYING

The final veneer can be dried with a drying machine. The moisture content can be around 14% for avoiding the risk of mold.

|  |